The components of the cartridge

In a cartridge there is a set of delicate and complicated production processes.

A cartridge is much more than a cylindrical object that we put in the shotgun. In a cartridge there is a set of delicate and complicated production processes. Only with the quality and good performance of each one of them separately, together with the appropriate combination of load and their correct dosage, give rise to the perfect cartridge so that when we aim and shoot we have absolute certainty that at that moment the shot will be executed with precision.

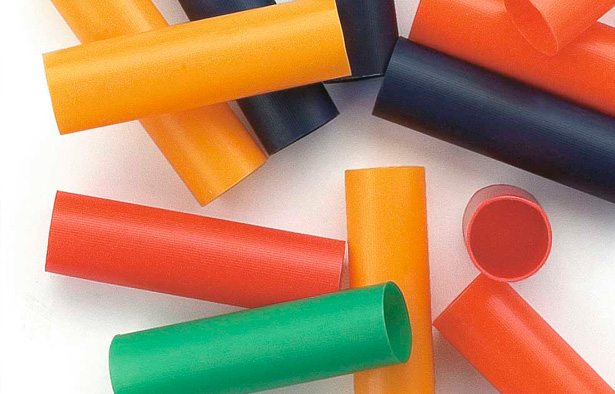

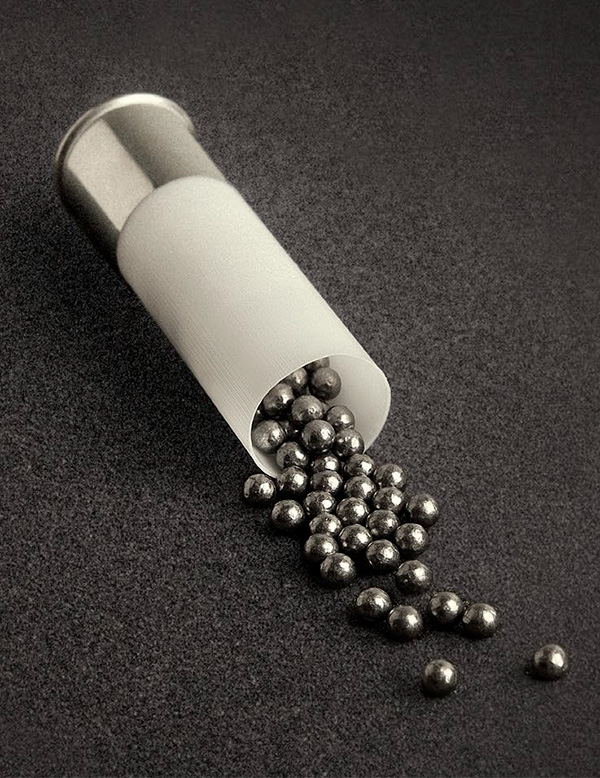

As in any recipe, everything begins with the ingredients, so the secret to making good cartridges, fundamentally lies in using good components. Said components are: Piston-Pod-Gunpowder-Taco-Perdigón.

If Nobel Sport Spain is privileged in something, it is in having the best components on the market, since it belongs to the largest European group of cartridge and component manufacturers. The group in its different plants in France and Italy manufactures gunpowder, plugs, pods and pistons. Therefore the quality, homogeneity and continuity of the components is always assured.